A-ROX Rail

A-ROX Rail

Precise GNSS-INS tightly coupled positioning system for railway applications

A-ROX Rail is a high-precision positioning and documentation system specifically developed for rail maintenance machinery and track-bound vehicles. Built on the proven ANavS® A-ROX platform and extended with railway-specific functionalities and certifications, it enables automatic and accurate logging and evaluation of work performed on railway tracks.

0.01m

Position accuracy

0.01 km/h

Velocity accuracy

0.05°

Heading accuracy

0.02°

Roll/Pitch accuracy

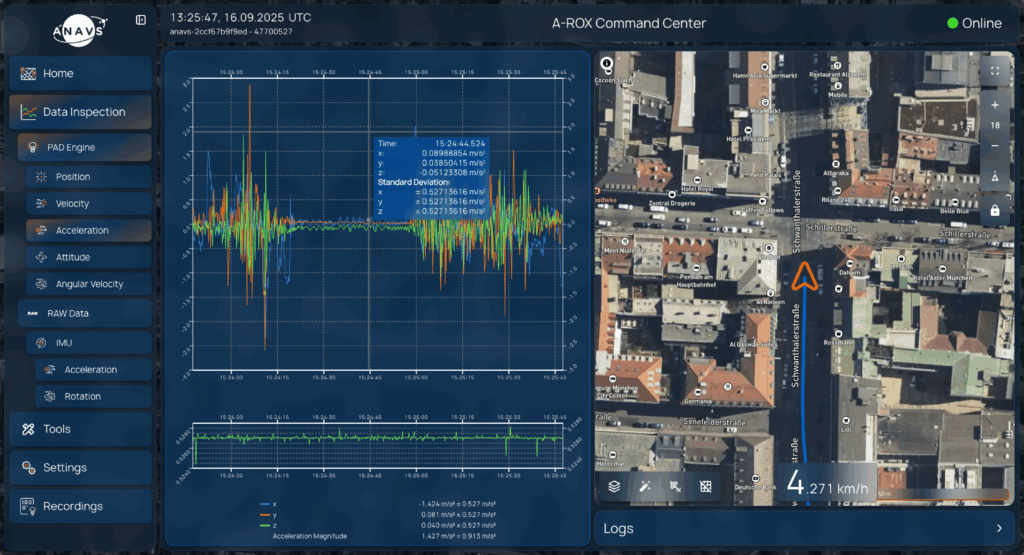

The ANavS® A-ROX Rail module provides precise position, velocity and attitude information, by tightly coupling GNSS, IMU and odometer data, and applying PPP or RTK corrections to the GNSS code and phase measurements.

The A-ROX Rail version supports RTK and Galileo High Accuracy Service (HAS) service (both via SIS and IDD) and OSNMA for navigation data accuracy. The A-ROX system comes with a ROS2 software architecture, which leads to access to all sensor raw data and solution outputs with ROS2 topics. This software architecture makes it very powerful for an easy integration in other toolchains and subsystems.

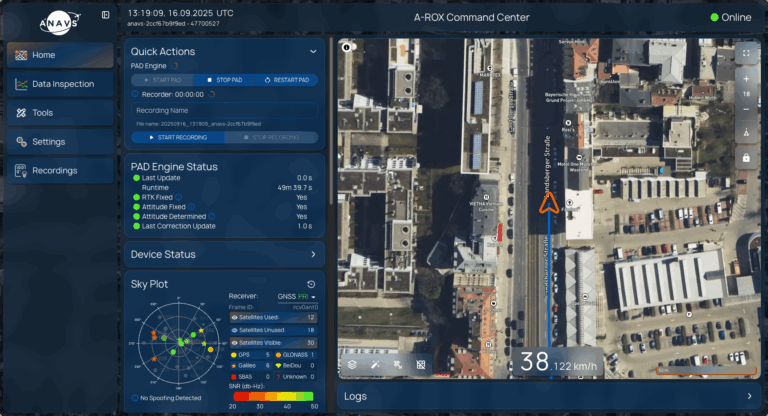

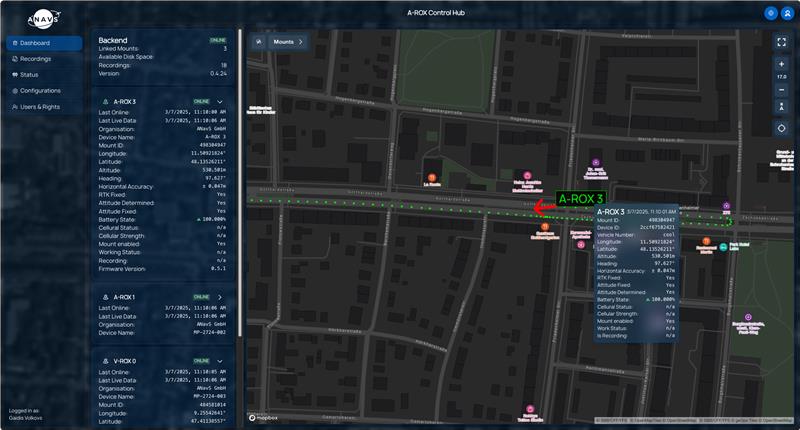

The powerful Command Center App together with the cloud based Control Hub completes the ecosystem of the A-ROX Rail. The new interface will make the system more accessible and user friendly. It will also open the door for its integration in fleet management systems, with the option to control all the devices in a centralised manner. A powerful postprocessing tool is hosted in the web-app.

A-Hub Software Suite for Railway Applications

Cloud-based User-Interface with Postprocessor, Fleet management system and work detection documentation

Precision,Efficiency and Control in One Platform

Our Fleet Management & Post-Processing System is a powerful backend platform that enables seamless monitoring, data analysis, and optimization of vehicle operations across various industries.

Autonomous Operation Features:

- Intelligent Power Management: The integrated mPOM Energy unit includes a rechargeable buffer battery. This allows the system to remain fully operational even when the vehicle is powered down, ensuring data continuity during idle phases or stops between worksites.

- Autonomous Mode Detection: The mPOM Connect module recognizes the active work mode of the track machine (e.g., tamping, grinding). Combined with movement detection and digital status inputs, the A-ROX Rail system autonomously starts and stops recording and positioning – no operator intervention required.

- Standby Mode with Smart Wake-Up: When inactive, the system switches to standby to save power, and automatically wakes upon motion or activation – ensuring immediate readiness with minimal power consumption.

Further Key Features

- Track-level accurate position and attitude estimation

- Automated detection of work mode on track machines

- Real-time cloud connectivity with 5G for live-view and backend processing

- Time synchronization with external systems (PPS and NTP)

- Full forward/backward post-processing and export to GTG (e.g. Swiss rail format)

- Web interface for system monitoring and configuration

- VPN-secured backend access

- Maintenance-free, suitable for both permanent and temporary installations

Application Areas

- Railway maintenance and construction

- Track machine (GBM) monitoring and recording

- Section-wise documentation of working areas

- Synchronization of machine data and positioning

- Geo-referencing and analysis for railway operators

Our features - Your advantage

Shaping the future of positioning – with customized solutions for every application.

Our product promise

Best possible positioning accuracy thanks to advanced GNSS sensors and integrated correction data service

Up to 2 GNSS receivers suitable for surveying – for precise positioning – are available. The raw data from all receivers is available (at up to 100 Hz). Compliant with railway certifications. An integrated modem enables the use of all correction data services available worldwide, such as RTK (RTCM3, OSR) or PPP correction data (RTCM3, SSR), without additional hardware.

Intuitive and simple handling

Modern web-based user interfaces with remote access, app, simple configuration, automated version management.

Can be used worldwide without special export restrictions

Duty-free import, no dual-use and export restrictions (ITAR-free).

No cable chaos

Internal WLAN and LTE modem, so fewer cables and devices are required in the test vehicle, fewer sources of error, i.e. one system – all functions.

Expertise advantage through R&D projects

Thanks to intensive research and development (R&D) projects, e.g. with the SBB, we have a knowledge and innovation advantage in order to develop advanced solutions and technologies faster and more effectively that have not yet been implemented in comparable systems (e.g. HAS, PPP, OSNMA).

Tightly Coupled Sensor Fusion Performance

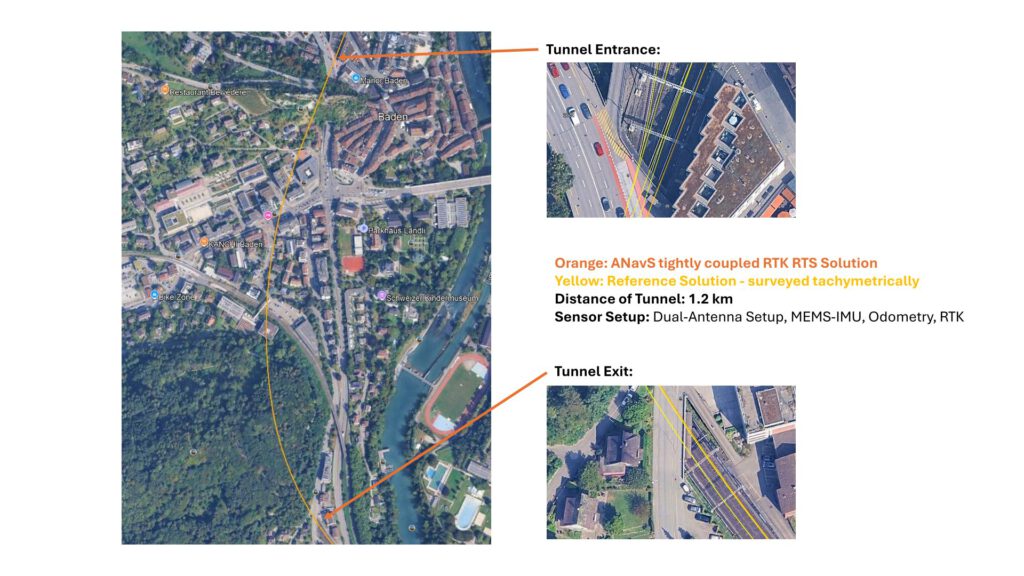

Our GNSS/INS/Odometry tightly coupled positioning and attitude engine demonstrates outstanding accuracy and robustness – even in challenging environments such as tunnel passages.

The left image illustrates the trajectory through a 1.2 km long tunnel (location: Baden, Switzerland):

Orange: ANavS® tightly coupled RTK-RTS (rauch-tung-striebel smoother) solution

Yellow: Reference trajectory, surveyed tachymetrically –

By combining dual-antenna GNSS, MEMS-IMU, odometry, and RTK correction data, the ANavS® solution remains stable even without GNSS visibility and delivers a trajectory that closely follows the highly precise reference line.

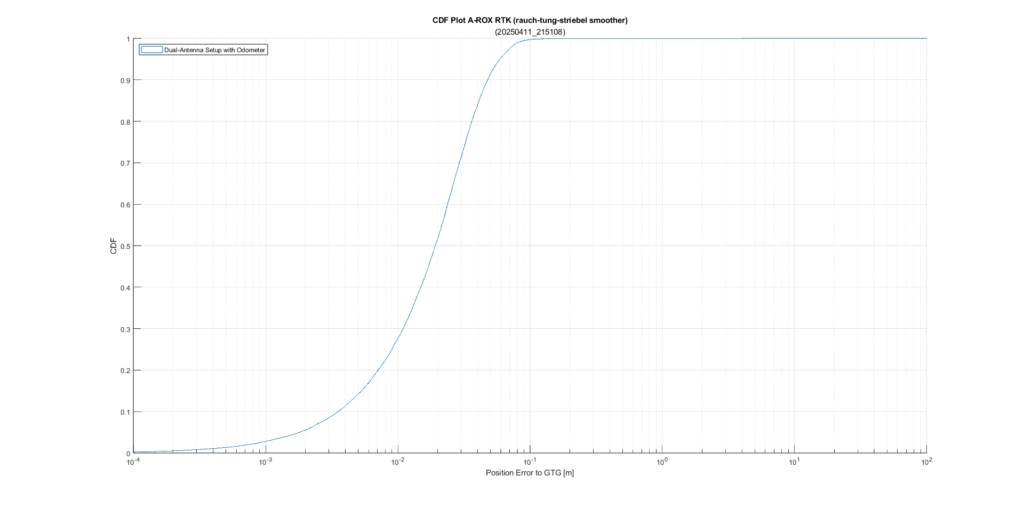

The right diagram shows the position error statistics (CDF). The results confirm that our tightly coupled fusion ensures very high accuracy ground truth and maintains solution integrity even during temporary GNSS outages.

With this technology, ANavS® provides reliable navigation for applications where continuity, precision, and robustness are critical – from autonomous driving to marine operations and demanding infrastructure projects.

Quick overview

Products

Equipped for every situation with the need of high-precise positioning & navigation: AI-ROX, A-ROX, G-ROX, MSRTK, Snow Monitoring and M.2 SMART Card.

R&D Projects

Our R&D team is constantly working on researching, developing and implementing new technologies to master the challenges of tomorrow.

Publications

Our publications are varied, provide well-founded findings and present innovative solutions: Journal and Conference papers, Patents and Theses